DSL-220 MkIII

Single Pass Opacity Monitor for monitoring opacity and smoke emissions

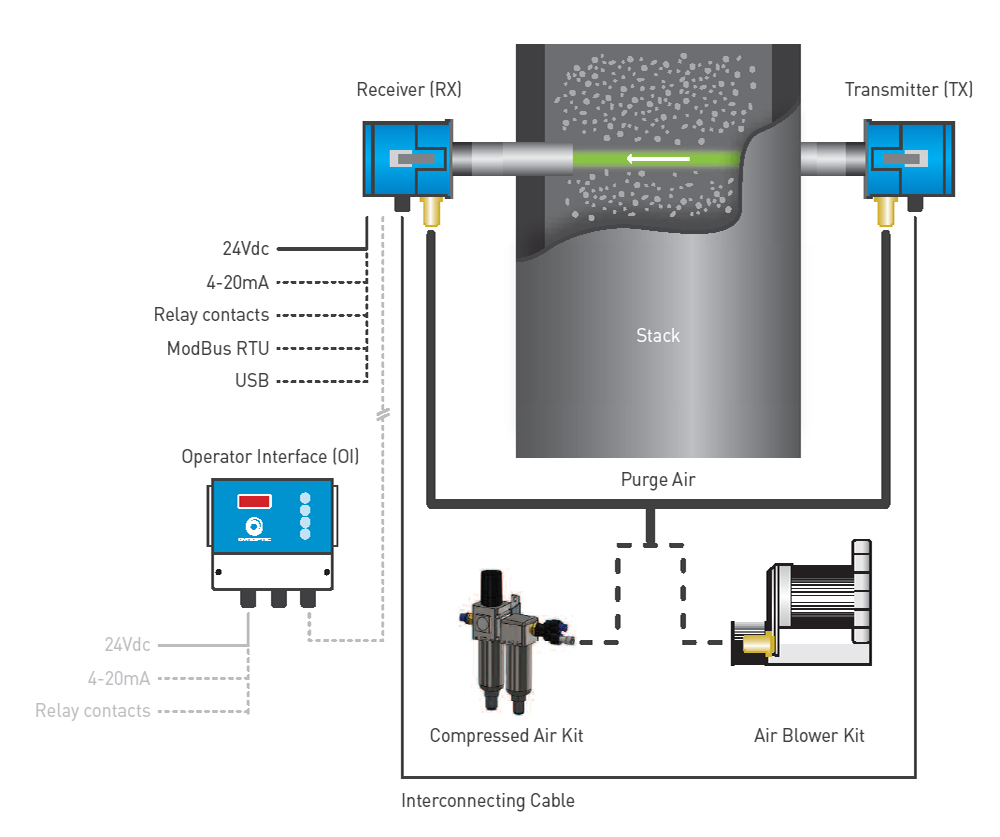

The DSL-220 Opacity Monitor is an optical instrument designed to measure the visible opacity of exhaust gas in a duct, stack or flue.

DSL-220 MkIII

The DSL-220 uses the single pass light transmission measurement technique, with Transmitter/Receiver arrangement. A light beam emitted from the Transmitter passes across the stack to a Receiver, which measures the intensity of the received light.

Increased particulate or smoke density in the stack gas attenuates the transmitted light and causes the intensity of the received light to fall. This reduction in intensity is measured and presented as % opacity. The higher the level of particulate or smoke present, the more light lost and therefore, the greater the opacity.

Optional accessories

- Operator interface (OI)

- 90-260 Vac model available

- Mounting flange installation kit

- Laser alignment tool to assist with installation

- Air purge blower kit (110 Vac / 230 Vac / 415 Vac)

- Compressed air purge kit

- Reference filters for routine calibration check of the instrument

Features

-

In situ measurement directly in exhaust gas flow

-

Measurement reading as % Opacity

-

Modulated green LED source for long lifetime stability and immunity to ambient light

-

Rugged 316 stainless steel construction

-

Choice of interface options enabling easy integration

-

Free utility software for PC based set-up control and data logging

-

Optional Operator Interface with different mounting configurations

Benefits

-

Low cost

-

Simple to install, commission and operate with an excellent reliability record

-

Rugged design with no moving parts so low maintenance

-

Latched head and lid design to enable ease of access for installation and maintenance

Specification

Measurement Performance

| No. | Parameter | Units | Min | Max | Comment |

|---|---|---|---|---|---|

| 1 | Path Length (flange to flange) | m | 0.5 | 20 | Flange-to-flange separation |

| 2 | Measuring Range | % | 0.0 | 100.0 | User selectable |

| 3 | Accuracy | % | -2 | +2 | |

| 4 | Resolution | % | 0.1 | Display resolution | |

| 5 | Damping | s | 1 | 60 | Selectable |

| 6 | Drift with Temperature | % | -2 | +2 | Over any 20°C in the operating range |

| 7 | Operating Wavelength | nm | 510 | 540 | Green LED |

Power & Air Requirements

| No. | Parameter | Units | Min | Max | Comment |

|---|---|---|---|---|---|

| 8 | Voltage | Vdc | +24 | Optional 90-260Vac PSU available | |

| 9 | Voltage Tolerance | % | -10 | +10 | |

| 10 | Nominal Current Consumption | mA | 400 | ||

| 11 | Power Up Current Consumption | mA | 400 | ||

| 12 | Air Supply Volume Flow | L/min | 50 | 200 | To each air-purge body |

| 13 | Air Supply Fitting | 1” BSP threaded aperture in each air-purge body | |||

Cable and Wire

| No. | Parameter | Units | Min | Max | Comment |

|---|---|---|---|---|---|

| 14 | Cable type – TX/RX Interconnection | cores | 6 | Screened multi-core, such as Belden 9873 | |

| 15 | Cable type – OI/RX Interconnection | cores | 4 | Screened multi-core, such as Belden 9873 | |

| 16 | Wire Size at Terminal Connections | AWG | 20 | 14 |

Interface Options

| No. | Parameter | Units | Min | Max | Comment |

|---|---|---|---|---|---|

| 17 | Serial Comms |

ModBus RTU via RS485 (OI or TRX) Internal USB (OI), external USB (RX) | |||

| 18 | Analogue Output (one) | mA | 4 | 20 | Isolated and scalable |

| 19 | Digital Relay Contacts (two) | A | 0 | 3 | @30Vdc (signal level and data valid) |

Physical

| No. | Parameter | Units | Min | Max | Comment |

|---|---|---|---|---|---|

| 20 | Ingress Protection: - TX/RX Heads | IP65 | For external use | ||

| 21 |

Ingress Protection: OI Wall Mounted OI Panel Mounted |

IP65 IP64 |

Hinged door and terminal compartment shut From front face of panel when installed | ||

| 22 | Ambient Operating Temperature | °C | -20 | +55 | Air temperature around the heads |

| 23 | Operating Humidity | % | 100 | Air humidity around the heads | |

| 24 | Gas Temperature | °C | +600 |

Heat insulating gaskets included (Higher temperatures on request) | |

| 25 | Regulatory Compliance |

2014/30/EU (Electromagnetic Radiation) 2014/35/EU (Low Voltage) | |||

| 26 | Materials: - TX/RX Heads | AISI/SAE 316L Stainless steel - Powder coated | |||

| 27 | Materials: - Air-Purge Bodies | Powder coated cast aluminium or stainless steel for demanding installations | |||

| 28 |

Materials: - OI Wall Mounted - OI Panel Mounted | UL rated polycarbonate enclosure; aluminium front panel with PU laminate overlay and with nylon cable glands | |||

| Powder coated steel back-box; aluminium front panel with PU laminate overlay and with nylon cable glands | |||||

| 29 | Weight | kg | 2.5 | TX or RX head plus Aluminium Air-Purge body | |

| 30 |

Weight: - OI Wall Mounted - OI Panel Mounted | kg |

1.3 1.3 | ||

| 31 | Warranty | months | 24 | Return to base warranty. Extensions available | |

Download brochures

ASK A QUESTION

For further information on any of our products, please complete our contact form and a member of staff will respond as soon as possible.

Altenatively call us on +44 (0)1280 850521

Satisfied clients

Don’t just take our word for it, read what some of our clients are saying about our products.

Product Applications

Below are our core product applications, simply select them for more information about suitable monitors